Last updated on 3 November 2018.

Quite a few of us have a Lada T132 sewing machine also known under many badge names such as Cresta, Minerva, Sewmaster, etc. It is a very nice rotary free arm machine from late 1950s and 1960s. All steel parts except two belts: a timing belt connecting the upper and lower mechanism, and the motor belt.

Timing belt

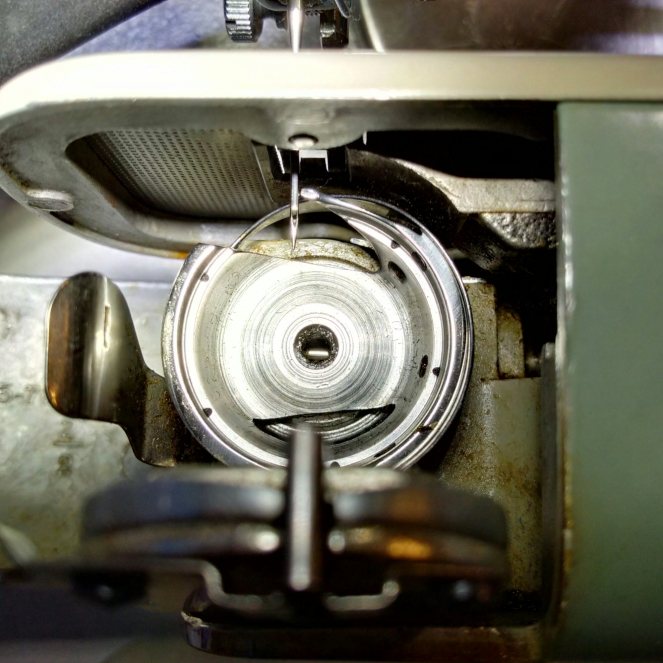

Lada T132 comes with two different rotary hooks that take different shuttles but the same bobbins.

They also take different timing belts.

The original belts look the same, so the teeth have the same trapezoid shape, 2.2mm high. However, they have a different pitch and the belts have a different length:

- The old style machines have a 376mm long belt with 50 teeth, giving a pitch of 7.52mm.

- The new style machines have a 382mm long belt with 47 teeth, giving a pitch of 8.13mm.

I realise that the pitch should be calculated at the gear level and not on the outside of the belt, but we only use it here for comparison. The important point being that an exact pitch is not necessary for the belt to work! Because both of these belts work with the same gears.

The original belt for the older machine (50 teeth) seems to be still available in the Czech Republic from this website. However, the website is entirely in Czech and they do not appear to post abroad. But one could always enquire, of course!

Both original belts are extinct in the rest of the world, so if your beloved T132 just had her belt snap, you were left with hunting down another T132 and scavenging her belt.

But not anymore! I have located replacement belts readily available:

- Old model: HTD 376-8M-10 (376mm long, 8mm pitch, 10mm wide, 47 teeth).

- New model: HTD 384-8M-10 (384mm long, 8mm pitch, 10mm wide, 48 teeth).

The new belts have been installed on actual machines and they are working!

These are not the same belts – the teeth have a different shape. But these belts are made of foam, so the teeth fill out the cavities in the gears and offer excellent grip.

Motor belt

The motor belt is unusually narrow and short. It is a V-belt that is 5mm wide, 3mm deep, with a 190mm inner circumference. It does not have a standardised ID.

Where to buy the belts

These belts are available from www.bearingsrus.com or www.bearingsrus.co.uk. The belts are not standard, so they don’t have them on the website, but if you drop them an email, they’ll supply both belts upon request. The belts are cheap and they even do multiple item discount starting already with two belts! (There are also other suppliers in the USA, but shipping to Europe is prohibitively expensive, and BearingsRus was the only one I found this side of Atlantic who did not charge me £20 per belt, but just £6.60, as it should be).

Fitting the timing belt

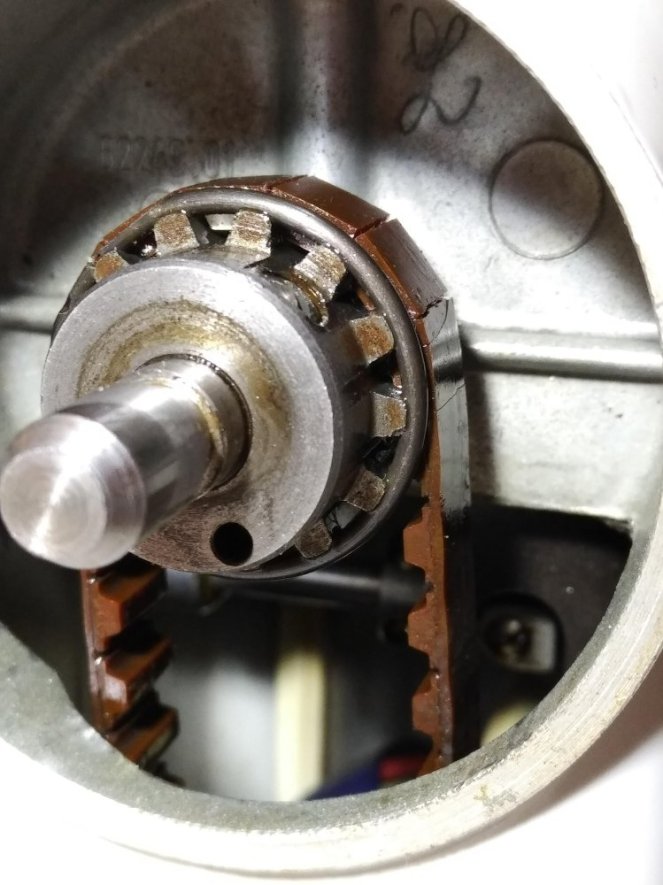

To fit the belt, remove the balance wheel by pulling it off – there’s a pretty strong spring, so pull hard. Under it, you have the top gear.

Remove the side motor cover, and behind the motor pulley you see the bottom gear.

Getting the new belt around the two gears is a pain, but can be done with perseverance.

I find it helps to soak the belt in hot water to soften it, as well as to remove the large motor pulley. Remember to put it back before continuing, though. See further down in this post for tips on fitting the motor belt.

Setting the timing

Once the belt is on, you need to set the timing which is tedious and also requires perseverance.

Remove the foot and insert a needle. Set the needle left.

Loosen the two positioning screws on the top gear.

Rotate the bobbin winder so that the hook is in the top position and the feed dogs are in the bottom position (the hook makes two revolutions for each stitch). Then rotate the shaft of the upper mechanism counter-clockwise until the needle reaches the lowest point and starts going up. The correct position is when the tip of the hook is aligned with the right side of the needle 1mm above the eye, with the needle in the left position.

Fix the positioning screws on the top gear and try some sewing. You are nearly there, but you will need to fine-tune the position for your machine, with perseverance. 🙂

Repeat the following: loosen one positioning screw on the top gear, rotate the shaft very slightly, tighten the screw, try sewing. Be sure to check straight stitch with the needle positioned left, centre and right, when all three work, zig-zag will work too.

Re-assembling

Remember to tighten both screws on the top gear. Then push the balance wheel back onto the shaft. The pin on the wheel goes into the hole on the gear.

Fitting and adjusting the motor belt

The motor belt can be quite easily pried off the larger pulley and also put back on. Fit the belt around the small motor pulley, then starting from the bottom, fit the belt into the groove of the large pulley as far as it will go. Rotate the motor pulley clockwise and help the belt get onto the large pulley.

Once on, the belt needs tightening. The tension should balance the tension of the timing belt so that there is no slipping. The new timing belt fits tighter than the original, so the motor belt needs tightening too. This is done by adjusting the position of the motor. It is mounted on the base plate with three large moveable screws accessible from underneath.

Final words

I have resurrected one old style T132 with the shorter belt (the one in the photos).

Dan Hopgood resurrected one new style T132 with the longer belt.

Both machines work, and we have so far not found any problems with the replacement belts. So I can offer you this solution with some degree of confidence.

Buy me a coffee 🙂

Buy me a coffee 🙂

Bonjour Elena et bravo pour toutes ces explications techniques. Je possède également une Lada Minerva T132 que je cherche à remettre en état de marche. Merci pour la référence de la courroie principale. Mais connaissez-vous la référence de la courroie du moteur sur le site de Beltingonline.com ? Au plaisir.

Vincent

LikeLike

Bonjour Vincent, je ne sais pas la référence, je acheté me courroies chez bearingsrus.co.uk. Et aussie la, je nais pas les trouvé sur le site mais je envoyé une email avec les mesures et reçue les courroies appropriers. Peut-être faut-il vous fair la même chose?

Bonne chance!

LikeLike

One of the good post with details on Timing belt. Do you deal in it?

LikeLike

Thanks! No, I don’t sell them – I simply needed to repair one such poor machine and was determined to find a belt replacement. 🙂

LikeLike

Thank you so much for this informative blog. I’ve had a Diplomat version of this machine for about 5 years and struggle with it a bit so this has really helped. I’ve added a photo because you didn’t mention Diplomat and I think the colour is more of a blue shade than green. https://imgur.com/gallery/5pDcdS6 We had issues finding a belt and ended up using a Cresta machine to steal the belt from. Might use Dan’s suggestion of Duct Tape and/or buy from beltingonline.com. Thanks everyone!

LikeLike