I chanced upon a very well preserved 1914 Singer 127K with sphinx decals that usually rub off very quickly. So why was this machine sitting in a cupboard all these decennia instead of sewing? Because it doesn’t sew. 😦

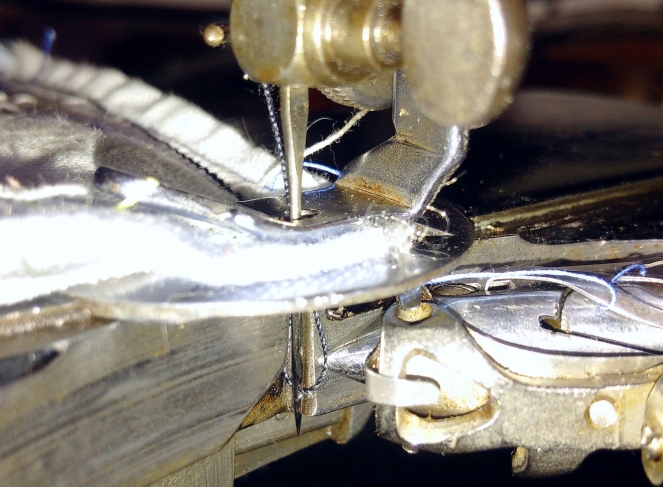

When the shuttle approaches the needle to catch the thread, the needle is too high, so the shuttle misses the loop. A typical timing problem.

First of all, it is worth while to check that the timing is not actually off. It is very difficult to knock it out of alignment on a vibrating shuttle machine because it is fixed in the joints, and I would not know where to begin fixing that.

But the check is very simple. Remove the face plate and rotate the balance wheel so that the needle is nearly at its lowest point. The mark should come into view. It should simply align with the tip of the shoulder on the right at about 14 minutes past the hour position. It won’t be very precise because there is a little play in that V-shaped driver.

Basically, as long as the mark is not horribly off, the mechanism should work.

The fact that the mark is in the right place on my unwilling to sew machine means that the shuttle carrier brings the shuttle to the meeting with the needle at the right time, yet a stitch cannot be formed. So the problem must lie with the shuttle or its cradle.

Of course now that I put the right and wrong pictures side by side, it is pretty obvious: the shuttle is too low.

The Singer 127K shuttle cradle is lined with a spring, so I thought perhaps the nose side of it had sagged?

I bent it up a bit, and things improved, but only for the first stitch. As soon as the thread was coming out of the shuttle, it was pulling the back bit up lowering the nose, and again we missed the loop.

I could not improve the cradle any further, so I turned to the shuttle. All Singer parts always have a Simanco part number engraved on them (Simanco stands for Singer Manufacturing Company), but this shuttle didn’t have such a number, although the spring did. This was the wrong shuttle!

Here is a comparison of the Singer 27K shuttle (Simanco part 8301), the mystery shuttle and a 1905 German Stoewer VS shuttle.

The mystery shuttle is the shortest of the three! It also has a rounded point instead of a sharp one. The German shuttle is very similar in shape to the original Singer 8301, but is almost a millimeter longer.

Both the Singer 8301 and the German shuttle work in the 127K. The short mystery shuttle also works in the Stoewer VS, but not quite as reliably as its own shuttle (some stitches get skipped). So for now I can use the German shuttle, but I’ve just ordered an original Singer shuttle for 127K, Simanco part 54504. We’ll see how that fares!

Buy me a coffee 🙂

Buy me a coffee 🙂

Thanks for the info Elena. I believe there are 3 versions of the 27/127 shuttle – though that does include the VS1,2 and 3 machines – as mentioned here – https://en.wikipedia.org/wiki/Singer_Model_27_and_127 though have been told that some of the information is not correct.

I’m getting back into sewing mode with my Vestas – they are turning out to be my favourite machines!

LikeLike

Good to hear you are finally back to sewing! 🙂

LikeLike

It seems that my mystery shuttle is one of those replacements mentioned in the Wiki page. Well, it doesn’t work! I’ve also just got out a 1933 Vesta VS3 (very rusty but working – 3-in-1 did its magic), and its shuttle is in length between the Stoewer and the Singer 8301, but it jams Singer 127K and does not work at all. A close inspection shows that it has a thicker nose, so it does not lie in Singer’s cradle properly.

Just goes to show how precise those measurements have to be!

LikeLike

I just got my grandmothers old Singer out of barn and someone has robbed the shuttles, etc. I’m so glad I finally looked long enough to find this blog. I know which machine it is now because of the shuttle holder. Thank you so much for posting. I hope I can find a shuttle. I remember my mom sewing on a treadle machine and I have done so. Brings back a lot of memories and now my 32 year old daughter is interested. GREAT!!!!

LikeLike

This is very exciting, thank you for sharing! Original Singer shuttles are very common, have a look on eBay or at Helen Howes’ shop: http://www.helenhowes-sewingmachines.co.uk. Both the new and the old versions work. And there is now even a reproduction shuttle available, brand new. 🙂 Also bobbins are common, original and reproduction. Nothing will stop you now! 🙂

LikeLike

I thought there was a problem with my 127 (the shuttle and carrier are both from a 27 – probably a fusion/intermediate machine). I could not get the bobbin thread up. Finally, twisting myself upside down to look at things as they moved, I realised that my needle (just a modern universal) was too short, so I dropped it down a bit until it reached about the bottom of the needle slot in the underneath (there’s probably a technical term for that) and bingo! everything’s just peachy now. So sometimes it’s not really the timing, nor the shuttle, but something as simple and fixable as a too short modern needle. Had me wondering and mucking about for near a week though!

LikeLike

It’s true, we often suspect something fundamental as timing when in fact the solution is much simpler. Well, it all has to work together, so any of the parts could be causing the problem! It is not always easy to see it though. 🙂

LikeLike

Thank you so much for this posting. I was given a White sewing machine circa 192?. I’ve had it a couple years but do not sew very much at all. I have tried using it a few times and each time it will or won’t make stitches, as it sees fit. I have scoured the internet, talked to my mother, and utilized my own mechanical knowledge. Your posting, along with Dakani’s reply and my mother’s advice have all come together to get the machine working. I have two shuttles for it, they are identical except that one is old looking with no markings while the other is new looking and is a Singer 54504. in the past I have used both with the same result, maybe it works maybe not. Dakani got me looking at the needle to shuttle relationship and I checked some other resources for more info and found that I needed to lower the needle about a millimeter. My Mother suggested that the all purpose thread that I bought at Walmart might be junk, ( she told me that she has bought thread that just would not work in the past) so I went to Joann fabrick and bought some good thread. I have found that with new thread, the needle lowered, and utilizing the SInger shuttle the machine works beautifully. The old looking shuttle causes the machine to skip stitches or not stich at all, and it looks just like the Singer shuttle. If I change any one of those items the, machine starts missing stitches. Until I read your article I though I was the problem. Now I have to find some things to sew!

LikeLike

I’m glad it all came together in the end! Sounds like your old shuttle might be damaged – it doesn’t take much and it’s not always obvious. Another idea is to try a thicker needle, I found that often helps with VS machines. I never had any serious problems with thread though, not in the sense of skipping stitches anyway. It is important to remember however that the needle must be thick enough for the thread, and poor quality thread is often a bit uneven with thick bits, and that’s where the needle gets too thin and skips stitches. I use normally size 90/14 with VS machines, or 100/16 for thicker fabrics.

LikeLiked by 1 person

I fixed my skipped stitches by changing the needle, as per your advice. Thank you!

LikeLike

Hello Elena! I am so glad that I stumbled across your blog. I have recently acquired a vibrating shuttle machine, which is missing it’s shuttle. And it appears to be one millimeter shorter than those that I have been able to find, as these are all too long to fit.

I am hoping that you might be able to point me in the right direction. I do not have the serial plate for the machine and am unable to locate the manufacturer. The machine is cast iron and read YUKON across the top. No other information is available. Do you perchance know whom could habe produced this machine? Or where I might be able to locate a shuttle, such as your mystery shuttle?

Hopeful for help,

Dusty

LikeLike

Hi Dusty, sorry but I don’t know how to identify your machine. As to where to find a shuttle, try eBay and similar sites, you might get lucky. Failing that, see if you can adjust the position of the cradle somehow so as to bring the shuttle forward. Some machines allow it, but it varies.

LikeLike

Hello Elena,

Thank you for responding. Sadly it is the overall length of the shuttle that is the issue and adjusting the craddle does not solve the issue. While I can move the craddle forwards or back, the seat of the craddle is a solid piece with no adjustment screws or areas that would allow for adjustment.

If you ever decide to part with the mystery shuttle that you mentioned in your post, I would be happy to relieve you of it, for a mutually agreeable price of course. 😉

Thank you again. Looking forward to continuing to explore your blog.

Best regards,

Dusty

LikeLike

Hello Elena

Thank you for this interesting post on timing of the VS machine. When I look at videos of the motion of the needle for long shuttle machines, it seems to be different than modern machines. The needle bar seems to be at a low point two times in a sewing cycle. And between the two points the needle only moves at bit up again. Is in at this position of a bit up again, that the thread should be catched, or is it later when the needle really is on its stoke upwards?

Best regards

Viggo

LikeLike

Please see my post “It’s all in the head”.

LikeLike

Sorry Elena. I actually found a video about it here, and I should have looked that up before I asked. This video shows, that the thread is catched when needle is between the two low positions.

BR. Viggo

LikeLike

Well, I now got 4 long shuttle machines and have started to learn about the mysteries of this kind of machines. I have started to check a Köhler VS3 machine. The mechanism to control the needle and take-up lever is completely different from the Singer 127. It is made by some arms and bearings – no slides except for the take-up. The needle bar got the two dips for each revolution of the handwheel as the 127. I found no markings on the needle bar, so I guess It just seems all right. This shuttle is 49.3 mm long.

Of cause the shuttle needs to catch the loop – no problem. Except for the height of the needle this timing is easy to get right, because the needle height do not move much when the the loop is catched. But I think the timing of the stroke of the shuttle in relation to the take-up becomes important on how the stitch is formed. For this Köhler, the timing is like this: First the shuttle advance to max forward position. At this position the take-up is still going up and is 6 mm from top. When the take-up is at max the shuttle have gone about 5 mm back from max forward position. So in a way, the shuttle is going a bit back while the position of the lock is formed until the take-up is at max.

I have got a bobbin tension of 0.22 N (as for normal sewing machine) and a needle thread tension of only 0.35 N to form a balanced stitch on two layers of denim. So only very low needle thread tension is needed for this machines compared to the normal shuttle hook machines I know of.

LikeLike

Hi there,

I just acquired what I think is a ‘Mundlos’ Treadle with Sphynx decals. The original owner told us it was a Mundlos, but I cannot find anything which would allow me to date it. OMG, It is gorgeous. It does have a shuttle bobbin. I am trying to date the machine and I want to get it working again.

Please help me get information on this machine and a manual if possible. Serial number is 2271724. It has the name Victoria on the machine as well.

LikeLike

If it is called Victoria, it’s likely to be Mundlos – this was their brand name. Try this website to date it: https://www.fiddlebase.com/german-machines/mundlos/dating-mundlos/

LikeLike

I have investigated timing between shuttle and take-up lever on three long shuttle machines I got. I do not have service manuals for them, and therefore I cannot be sure, that they got the right timing. For a Gritzner 1 and a Singer 48k, the lower thread tension is deemed to be zero when the take up lever apply upper tension to form the stitch, because the the shuttle have moved back from forward position, when it happen. Furthermore the upper tension is zero (except for take-up spring) when the shuttle pulls with the bobbin thread tension. I got this table of the measurements I made:

https://drive.google.com/uc?id=16rBaLPcayzLAtTpUYrmpnDeU2bPT7Zxz

I have unsuccessfully tried to find more information about this subject and tried to collect information in two forums. I know that the Singer 27/127/28/128 is quite well specified, so perhaps someone some day tries to measure the same table values, so i can compare. You are able to change timing significantly on these Singer Machines, because the Main cam for the take-up lever got two lock screws to the main shaft. This source gives more accurate information on timing on these machine, than the adjusters manual:

https://www.singersewinginfo.co.uk/28timing

If the right timing is so, that the shuttle have not moved much back when the take-up lever form the stitch, then I guess the bobbin thread tension becomes more important for the stitch forming.

LikeLike