This is a full size vibrating shuttle machine based on New Home design. Mundlos serial number is 1816620, and according to fiddlebase.com it puts it right into the middle of World War II in 1942-43.

The machine was branded “Empire” – I refreshed the lettering and added “Mundlos” because I like to see the maker’s name on a machine. The correct model name is Mundlos 100. I also improvised with the border on the front edge where the decals got rubbed off. 🙂 I cleaned the metal bits and varnished the machine. It is still a little dull at the moment because the polyurethane varnish is still curing – I shall polish it up in a few weeks time. Other than a bit of a clean, there was nothing to do here! 😀

Compared to the Singer and White vibrating shuttle designs, the New Home design sits in the middle – the swinging arm is not as short as on Singer and not as long as on White but in-between, with the centre of rotation about half way on the machine bed.

Another important difference in this design is the use of gears in the “rump” of the machine instead of a universal joint to transfer rotation from the balance wheel to the needle and the mechanism under the bed.

Old transverse shuttle machines had gears, but Singer 15, 27 and 66 had a universal joint, as well as White VS and Rotary. New Home however kept the gears. Singer returned to the use of gears in model 201.

Compared to the actual New Home VS machines, this version by Mundlos has several Singer-style features that have become pretty much standard in Europe in early 1900s: the 15×1 needle, the low shank foot fitting and the bed size of the machine with standardised hinges. The shuttle is of course proprietary as it matches the shape of the race, but the bobbin is standard – the same size that all the other VS machines use. The bobbin winder has a positioning pin, so make sure to buy bobbins with a little hole in the cap.

Mundlos re-designed the take-up lever mechanism and filed a patent in 1903.

Their machines no longer have a cover plate on the front characteristic to many other machines of the time. According to the patent text, the change was not only cosmetic – it actually improved take-up action. I cannot confirm or deny that the action is improved – both mechanisms work fine, based on my experience. No problems with take-up. 🙂

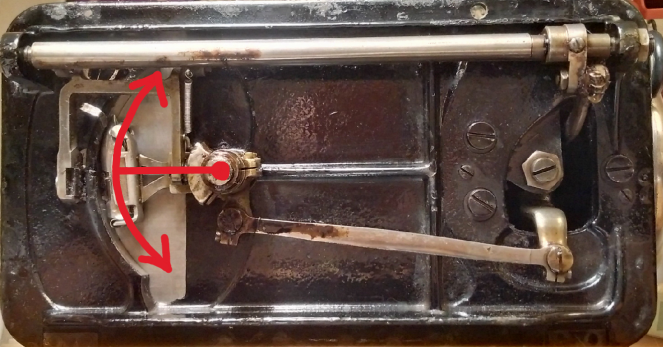

Finally, the feed mechanism is a bit different. The feed is rocking on two axes both running along the length of the bed of the machine (the front axis is a little shorter than the full length). The feed dogs are mounted on a bar that is fixed between the two axes with pivot joints.

The vertical movement of the feed is driven from the central joint that also moves the shuttle. The movement is transmitted by the front axis into the bar with the feed dogs. The horizontal movement of the feed is driven from the main column and transmitted by the back axis into the bar with the feed dogs. The resulting elliptical path of the feed dogs is completely axis-driven – there is no spring that would keep the feed dogs submerged on the way back as in many other feed mechanism designs. This mechanism gives a very consistent feed.

But now for the most important bit of all: how does it sew? Very well. I really like the feel of this machine. Although the gears in the “rump” require a bit more power to get going, they feel smoother than a universal joint during longer stretches of work. Overall, this appears to be a very capable machine. It has a good feed which is both delicate and effective – it managed to get a flexible stitch on the finest jersey with 45% stretch, which is slightly above the other VS machines. This is because it was able to make slightly shorter stitches than the other machines and to pack more thread into them, all without stretching out the jersey. Of course, Singer 48K still outperforms it on stretch, but that was to be expected.

I tried all sorts of fabrics with Mundlos 100, and it made a good stitch on all of them, with remarkably little knob twiddling. This is the one big advantage of this machine over the other VS machines in my sewing room: it appears to require less adjustment than most. May be that patented take-up mechanism actually does make a difference? Or may be it’s the different feed mechanism and a better adjusted foot pressure spring that form the defining factor? Or the “middle of the road” swinging arm in the underbelly? Or the gears in the “rump”? Or may be simply, just like in Singer 48K, it’s all of these things put together, with a sprinkling of fairy dust.

Interesting! I find it fascinating that some designs of machine last(ed) so long in the history of sewing machines. I have a The Free No. 5 treadle which is based on the Singer 27/28 model. It took awhile to “get” the filling of the bobbin and the bobbin casing, but it works. You have me interested in the Singer 48 now – but do I need another machine? Or more frustration? I found the treadle’s set-up very trying, in part because of a lack of good illustrations on the bobbin / casing situation – until I learned that it was a replication of the Singer – then, YouTube helped! Again, fascinating stuff. I think I like the Singer 66 set-up the best of vintage machines – drop in bobbin, and if I recall, the left-to-right needle threading. Stay healthy and keep posting!

LikeLike

Yes, the 66 setup gave rise to all those drop-in bobbin mechanisms too. It’s easy once you “get” it – I had trouble figuring out how to lead the thread through an open mechanism! I was used to putting a bobbin into a bobbin case on my previous machines. It all comes down to what you’re used to! I was lucky to find a manual for a vibrating shuttle machine early on, so immediately learned how to thread the shuttle without having to figure it out myself. 😉 I remembered how to use the treadle from when I was a child – my grandmother had one. But I prefer a motor these days – I got lazy (also I have knee arthritis).

Regarding Singer 48K – I’m sure you don’t need it, but that’s hardly the point, is it? 😉 Hehe.

LikeLiked by 1 person

I have knee issues, too, but use two feet to treadle, one in front, one in back. As far as needing new machines – to me, not necessarily newly manufactured (but you know that!) – yeah, I really don’t!

LikeLike

Interesting! I’m just getting into VS machines. My Singer 28 worked fine on thin cotton jersey, but skipped stitches and had tension problems on thin viscose/cotton jersey. The Singer 634 chain stitch worked fine on viscose/cotton, but made no end of trouble with the cotton jersey. Waiting for a Stoewer Serata to arrive (branded Velocitas, danish I think), curious about how it will work. I’m enjoying yor posts thoroughly, love the combination of both sewing and mechanical knowledge.

LikeLike

Thanks! In my personal opinion, Stoewer’s Serata is the finest vibrating shuttle machine among the ones I’ve tried (English and German mostly). I do like this new Mundlos 100 but I think I still prefer Serata… Good luck with it!

LikeLike

Love the new decals – fun! Fairy dust works for me. Not really noticed the Mundlos machines before – you do a super job in highlighting faults (if any) and introducing interesting machines. Thank you.

LikeLike

They were known as “Original Victoria” as well. The VS design dates back to the early 1900s, they’ve been making them in full size, three quarter and half size. Quite a few of them are around in the UK – they are very nice machines. Mundlos made other models too, for example the vertical oscillator model is known here as “Pax”. It’s one of the oldest German sewing machine manufacturers, not huge in numbers but standing out with quality, so I got very excited when I realised that this “Empire” was in fact Mundlos. I wonder how it made it to the UK though – I don’t believe there were any imports going on from Germany in 1943. 😯 Yet it was housed in a typical UK case, so could there be still some sewing machine smuggling going on? 😲

LikeLike

I understand that all reference to being German machines was removed and department stores would pick a name for them as a cunning disguise! Still too good a machine to not import and possibly cheaper than our own manufactured machines. I’m guessing that iron was in short supply having been used for arms, planes, shells etc.

I have a Vesta, it’s marked Kerry, but only the snakeskin (and model shape) is the giveaway. Underneath there is a very faint imprint of a triangle in the iron. Same happened around WW1 too but unnecessary many years later to continue the cover up. I wondered if the Kerry name was to do with Ireland – although that would be in gaelic perhaps. Or maybe the surname of the importer? There are not many that I know of – the only other Kerry was a different model and was offered as parts only in the US years ago. There were also names like Sylvia on similar models – anything but Dietrich! LOL. Underneath the lid is marked with May 1925 – and I thought she was around the mid 1930s! I call her Mini me!

LikeLiked by 1 person

Hi Elena, I know you mentioned using a New Home clone but just found this blog. We have been fixing our New Home here and it was a bit stiff. Since the belt cover is over any oil hole for the main shaft bushing coming off the hand wheel I removed the side cover, oiled the gears and bushings exposed then tilted the machine towards the rear and then put white (clear) sewing machine oil as the hand wheel was turned. Since everything else had been oiled this was last step and wow does it turn smooth and easy as any machine we have here. No hard startup at all here now. Now to make a custom presser foot tomorrow as ours came without one. Step by step restoration 🙂 Have to wonder if the feed dogs are compatible to any others so I can try alternating the teeth height. Best regards, Mike

LikeLike

Glad it’s coming along! I usually oil every moving joint, not just the oil holes. I find there’s always something being missed otherwise.

LikeLike