I found her sitting by a street bin, abandoned.

This is Vesta Saxonia TS, serial number 1477490, made in 1924, according to fiddlebase.com. Complete and working.

This is a small model – what they call “half size”. It has the typical geared Saxonia balance wheel with integrated handle – this is a hand-crank and the balance wheel rotates clockwise, like a hand-crank. The gears make for very light going.

Of course, I don’t need yet another machine! But it’s hardly the point, is it? 😉 This little Vesta makes for an excellent garden machine for doing a little project in the garden on a Summer afternoon and not having to bother with pedals and wires. It is small and light enough to be carried around! 😃 I decided to give it a spot of TLC and make it work properly.

In many ways this machine is similar to Vesta B that I used as a prototype in my needle conversion project. So much so that I could even reuse some photos where the parts are the same! 😏 The rusty ones are from Vesta B.

But now for that TLC.

First, the needle. This machine was made to use 12×1 needles but it had a DBx1 needle in it, which sort of fitted, but not very well. DBx1 wasn’t fully centred but still it went through the hole and it could sew.

However, the thick end came too low and was going into the fabric. So the needle bar had to be raised a little. There isn’t much room to raise it in these machines because the take-up lever fits through a slot in the needle bar, and raising the needle bar too much would make the take-up lever hit against the bottom of the slot when the needle is up. Also, the needle clamp hits the base of the head.

But I only needed to raise it a little bit, and managed about 2mm. It kept the thick end of the needle safely out of the fabric – success! But now the DBx1 needle was too short and the machine was skipping stitches.

There is a longer version of the same needle: type 108×1. It is about 4mm longer than DBx1 but is otherwise the same, and I already used it in other old machines, notably a 1885 Wertheim TS. These needles are used in industrial button sewing machines for jersey, so they only come in one point type (jersey) and commonly just in sizes 80 and 90. But actually this is all you need for most fabrics, so I think it is a good choice. And it is working perfectly with my little Vesta!

Raising or lowering the needle bar in machines of this design also requires re-adjustment of the take-up lever. In Vesta TS there are two rods that limit the rise of the take-up lever in two places regulating the movement.

The long rod is supposed to have felt in the end of it to cushion the noise of the take-up lever hitting against it – there was still a little left in Vesta Saxonia. The rod screws into the needle bar. The second regulator is the screw behind the needle bar on the top of the head. Since I only raised the needle bar slightly, these two regulators only needed a small adjustment to prevent the take-up lever hitting what it should not.

It is amazing what a difference 2mm makes. Now that the needle bar got raised, the foot presser bar could also be raised a little to get a decent foot clearance and an evenly regulated pressure. The spring was too short so that the foot pressure adjuster was only having some effect when it was nearly completely in. I added a soft spring first for fine tuning of low pressures, then put a different main spring so that the total length came exactly to the top of the head ensuring that the whole length of the adjuster was doing something.

This machine has automatic tension release when you lift the foot – it is done with the pivoting bit mounted on the back of the face plate. It wedges a finger between the tension disks – simple and effective.

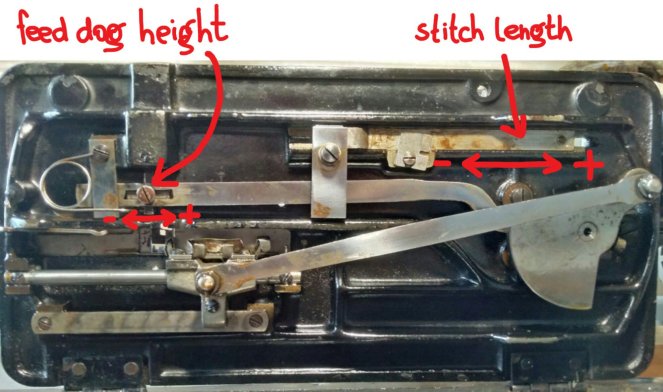

Next up was the feed dogs height. The maximum stitch length was too short – only 2.5mm. There is no generic maximum stitch length of course but it is usually at least 3.5mm.

This machine has the old style feed mechanism with flat bars, and the feed dog height appeared to be a bit of a diva: a tiny bit too high, and the machine sews in place because the feed dogs don’t get fully submerged on the way back. Which is why it is safer to set it too low. But I managed to find the sweet spot and got stitch lengths from 0.5mm to 3.5mm.

The little Saxonia was sewing better than Vesta B where I could not get anything but high tension from the bobbin. Yes, we have a better shuttle!

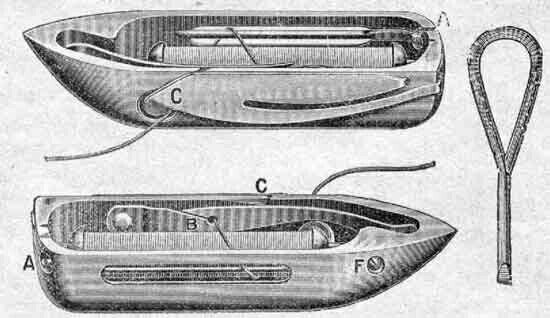

These shuttles are very similar and take the same bobbins, but notice the difference in the spring design. It doesn’t look like much but the new design delivers a much wider range of tensions with the other components being the same. In particular, it is not this outer spring that regulates tension but the inner spring in both designs.

Screw F regulates tension exerted by spring B. Spring C is only preventing the thread from flopping about! Yet it is making a big difference.

Finally, the bobbin winder was stuck.

Normally it is retracted as in the above photo, so that the brass gear is not engaged. You are supposed to press on the lip on the front black bit to engage it – you see the paint wore out a bit just there. But nothing was happening even after oiling everywhere.

Turns out, it was the regulating plate that was jamming it. When the bobbin winder is engaged, it flips forward the thread guide. You can see now the bit against the main column with a rectangular plate and a screw in it, engaging a jagged edge. This plate can be moved more towards the back or towards the front so that it engages the jagged bit such that the brass gear of the bobbin winder meshes with the teeth on the inner surface of the balance wheel.

Yet, something feels wrong with this bobbin winder. Let’s thread it up!

Definitely wrong! The thread guide for even winding of the bobbin is on the wrong side of the guide unit! 😮

That arched guide is supposed to direct the thread and make the bobbin wind smoothly, but it is not on the thread path here! The result is the bobbin wound rather unevenly. 😒

This thread guide unit belongs to a bobbin winder for regular machines where the little wheel driving the winder is pushed against the outer rim of the balance wheel – it is pushed back. On a Saxonia machine the winder driver (the brass gear) is pushed forward, so the thread guide unit has to have the arched guide on the other side. We’ll never know what happened with this machine, but it ended up with the wrong guide in the bobbin winder!

But, you can still wind a bobbin, and I guess that’s the important bit.

All in all, this is a really nice little thing. She sews well and is a pleasure to use. Worth while a varnish! And did you notice – I already took her into the garden! 😁

glad you came across her, you know what to do. Lovely little machine. That thread guide is a mystery…

LikeLiked by 1 person

I am glad at least they put it out in the street and didn’t take it to the tip straight away. 🙂

LikeLike

I have this Little Vesta machine and have the same type of thread winder. I have a great deal of difficulty in trying to make it work. Your article has helped me a bit. Thanks.

LikeLiked by 1 person

Elena, you have a book in you about repair & adjustment of these old machines. Just planting a bug in your ear!

LikeLike

Very sneaky, that! 😆

LikeLike

Oh what a delightful discovery. I am so glad you were able to figure out all her secrets and get her up and running. How lovely that she enables you to work on projects out of doors, especially on a spring day.

LikeLike

I find it always so satisfying to revive something. 🙂

LikeLiked by 1 person

I love your posts on old sewing machines and what a great rescue – wow just sitting around in a bin!

LikeLike

Well, the previous owners no longer wanted it. At least they didn’t destroy it!

LikeLike

Elena – so so love these machines – I guess I could say it’s in my favorites – I have two so will need to take a good look at your post. Will send you an email soon! Life has been hectic to say the least but have loved reading your posts!

LikeLike

I am curious what sort of bobbin winder yours have. 🙂

Things have been hectic here too – what with the new puppy and then lockdown of course. All existing routines got disrupted! At least one advantage of working from home is that I can sit in the garden, at least some of the time. 😉

LikeLike

Oh how lovely. How sad that it was dumped by a bin! So lucky it wasn’t raining. She has found a lovely home.

LikeLiked by 1 person

What a marvelous find. I wish I would find a machine like that!

LikeLike

Hi, I just found an identical model in a 2nd hand shop and snapped it right up. she runs very well but needs some tlc to look her best. I am a little confused about her date though as i keep finding conflicting reports on the age of this particular model. Mine also has a serial number that Isn’t close to any other I have seen. Serial No. 1220460. I was wondering if that makes it an older model. Any info you could share would be supremely helpful

LikeLike

Hi, there is a bit of confusion about serial numbers there. Different sources on the Internet have different information. Your guess is as good as anyone else’s!

LikeLike

There is a Vests available in my area, but she’s missing her shuttle (bobbin case). They seem so precisely made, any idea where to buy one?

LikeLiked by 1 person

Trarie, you can’t buy these shuttles any longer. There were also several models with Vesta Saxonia, and they are not interchangeable (don’t fit).

LikeLike

Does anybody know where I can purchase metal spools for this type of Vesta sewing machine. I managed to purchase some which appeared to be made of some type of plastic or resin, but unfortunately they don’t seem to be strong enough and bits are flaking off. I only have one metal spool and would love to have some more.

LikeLike

Jon Helig is where I obtained more long bobbins for my Vesta Saxonia. He makes them.

LikeLike

On your Vesta Saxonia, I have the exact same machine and bobbin winder. You can make adjustments so the bobbin is on the correct side of that arm. I initially had the same issue but after looking at your post, then adjusting the stop/ratchet position fixed the problem.

LikeLike

I have an “original Saxonia” I have looked around to try and find something out about it but all the pictures and comments are about Vesta saxonia. Does anybody know about this square one (not fiddle shaped at the base)

LikeLike

It’s just a later model, when fiddle shape went out of fashion.

LikeLike

Hi Elena. Thank you for taking the time to reply.

I can take it my Saxionia Original is not a very valuable antique. Would you know there anywhere I could get an instruction manual, as I would love to see what it can do.

Kind Regards Jenny

LikeLike

Hi Jenny, I don’t think there are instruction manuals. But it is a transverse shuttle machine, so perhaps one for Singer 12 would be helpful. It is very similar. You can get the manual on the Singer website (yes, even such an old one).

LikeLike